Page 39 - Curriculum Visions Dynamic Book

P. 39

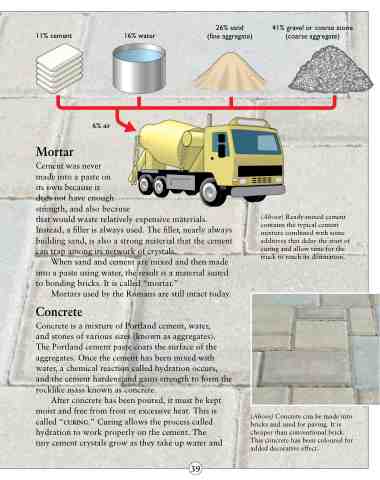

11% cement

16% water

26% sand (fine aggregate)

41% gravel or coarse stone (coarse aggregate)

Mortar

6% air

Cement was never

made into a paste on

its own because it

does not have enough

strength, and also because

that would waste relatively expensive materials. Instead, a filler is always used. The filler, nearly always building sand, is also a strong material that the cement can trap among its network of crystals.

When sand and cement are mixed and then made into a paste using water, the result is a material suited to bonding bricks. It is called “mortar.”

Mortars used by the Romans are still intact today.

Concrete

Concrete is a mixture of Portland cement, water,

and stones of various sizes (known as aggregates).

The Portland cement paste coats the surface of the aggregates. Once the cement has been mixed with water, a chemical reaction called hydration occurs, and the cement hardens and gains strength to form the rocklike mass known as concrete.

After concrete has been poured, it must be kept moist and free from frost or excessive heat. This is called “curing.” Curing allows the process called hydration to work properly on the cement. The

tiny cement crystals grow as they take up water and

(Above) Ready-mixed cement contains the typical cement mixture combined with some additives that delay the start of curing and allow time for the truck to reach its destination.

39

(Above) Concrete can be made into bricks and used for paving. It is cheaper than conventional brick. This concrete has been coloured for added decorative effect.