Page 37 - Curriculum Visions Dynamic Book

P. 37

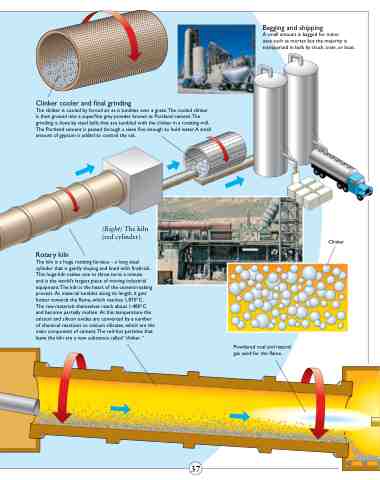

Clinker cooler and final grinding

The clinker is cooled by forced air as it tumbles over a grate.The cooled clinker is then ground into a superfine grey powder known as Portland cement.The grinding is done by steel balls that are tumbled with the clinker in a rotating mill. The Portland cement is passed through a sieve fine enough to hold water.A small amount of gypsum is added to control the set.

(Right) The kiln (red cylinder).

Rotary kiln

The kiln is a huge rotating furnace – a long steel cylinder that is gently sloping and lined with firebrick. This huge kiln makes one to three turns a minute

and is the world’s largest piece of moving industrial equipment.The kiln is the heart of the cement-making process. As material tumbles along its length, it gets hotter towards the flame, which reaches 1,870°C.

The raw materials themselves reach about 1,480°C and become partially molten. At this temperature the calcium and silicon oxides are converted by a number of chemical reactions to calcium silicates, which are the main component of cement.The red-hot particles that leave the kiln are a new substance called “clinker. ”

Clinker

37

Powdered coal and natural gas used for the flame.

Bagging and shipping

A small amount is bagged for minor

uses such as mortar, but the majority is transported in bulk by truck, train, or boat.