Page 36 - Curriculum Visions Dynamic Book

P. 36

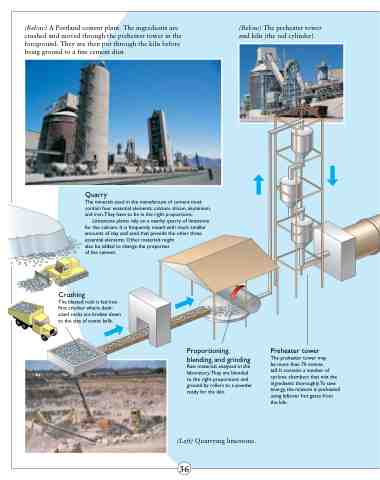

(Below) A Portland cement plant. The ingredients are crushed and moved through the preheater tower in the foreground. They are then put through the kiln before being ground to a fine cement dust.

(Below) The preheater tower and kiln (the red cylinder).

Quarry

The minerals used in the manufacture of cement must contain four essential elements: calcium, silicon, aluminium, and iron.They have to be in the right proportions.

Limestone plants rely on a nearby quarry of limestone for the calcium. It is frequently mixed with much smaller amounts of clay and sand that provide the other three essential elements. Other materials might

also be added to change the properties

of the cement.

Crushing

The blasted rock is fed into first crusher where desk- sized rocks are broken down to the size of tennis balls.

Proportioning,

blending, and grinding Raw materials analysed in the laboratory.They are blended to the right proportions and ground by rollers to a powder ready for the kiln.

(Left) Quarrying limestone. 36

Preheater tower

The preheater tower may

be more than 70 metres

tall. It contains a number of cyclone chambers that mix the ingredients thoroughly.To save energy, the mixture is preheated using leftover hot gases from the kiln.