Page 41 - Curriculum Visions Dynamic Book

P. 41

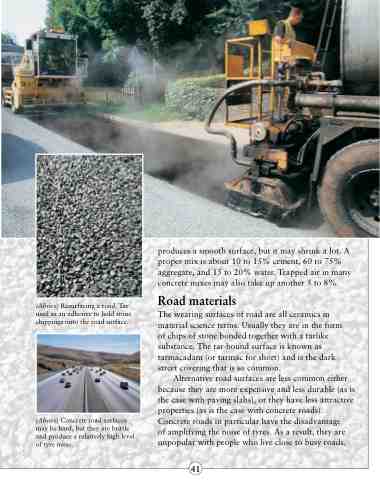

(Above) Resurfacing a road. Tar used as an adhesive to hold stone chippings onto the road surface.

produces a smooth surface, but it may shrink a lot. A proper mix is about 10 to 15% cement, 60 to 75% aggregate, and 15 to 20% water. Trapped air in many concrete mixes may also take up another 5 to 8%.

Road materials

The wearing surfaces of road are all ceramics in material science terms. Usually they are in the form of chips of stone bonded together with a tarlike substance. The tar-bound surface is known as tarmacadam (or tarmac for short) and is the dark street covering that is so common.

Alternative road surfaces are less common either because they are more expensive and less durable (as is the case with paving slabs), or they have less attractive properties (as is the case with concrete roads). Concrete roads in particular have the disadvantage

of amplifying the noise of tyres. As a result, they are unpopular with people who live close to busy roads.

(Above) Concrete road surfaces may be hard, but they are brittle and produce a relatively high level of tyre noise.

41