Page 20 - Curriculum Visions Dynamic Book

P. 20

and become hard, strong, and waterproof. The clay also shrinks slightly as the water is driven off.

It is important not to let vitrification go too far, for the secret is just to cause fusing, not melting, or the ware will lose its strength and sag while in the kiln.

The temperatures at which this happens vary between 1,600°C and 3,300°C depending on the materials used in the ceramic.

Glazing

Even after firing, the ware is not necessarily watertight (impermeable). To make it completely impermeable, glass is crushed up and suspended

in a liquid. This pulverized glass

will make a glaze (a protective and decorative coating).

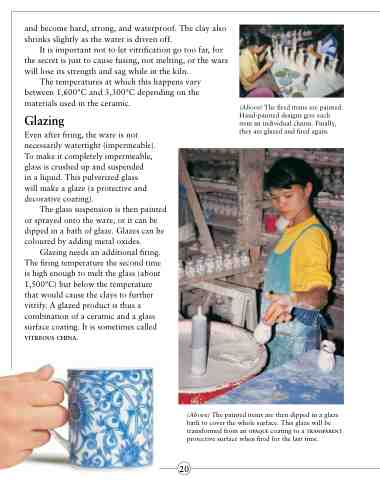

The glass suspension is then painted or sprayed onto the ware, or it can be dipped in a bath of glaze. Glazes can be coloured by adding metal oxides.

Glazing needs an additional firing. The firing temperature the second time is high enough to melt the glass (about 1,500°C) but below the temperature that would cause the clays to further vitrify. A glazed product is thus a combination of a ceramic and a glass surface coating. It is sometimes called vitreous china.

(Above) The fired items are painted. Hand-painted designs give each item an individual charm. Finally, they are glazed and fired again.

(Above) The painted items are then dipped in a glaze bath to cover the whole surface. This glaze will be transformed from an opaque coating to a transparent protective surface when fired for the last time.

20