Page 19 - Curriculum Visions Dynamic Book

P. 19

inside the clay crystals. This water can only be removed by stronger heating. At the same time, such heating burns off any impurities such as bits of organic matter.

After drying, the clay is fired. The oven, which is called a kiln, is loaded with ware, and it is heated up. Once the batch is sintered, it is taken out, and a new batch put in. However, working batch by batch is not suitable for mass producing articles such as bricks. In the case of large-scale mass production tunnel kilns are used: Continuous belts carry the material slowly to the hottest part of the kiln and then back out again.

Vitrification

The word vitrification means to turn to glass. It is what happens in the kiln when the edges of the clay platelets begin to turn glassy and fuse together.

During vitrification some of the glass flows into the pores between particles and helps fill them up. Small particles also fuse together with the larger particles. This produces a denser material and also makes the ware watertight. Only then does the clay change permanently

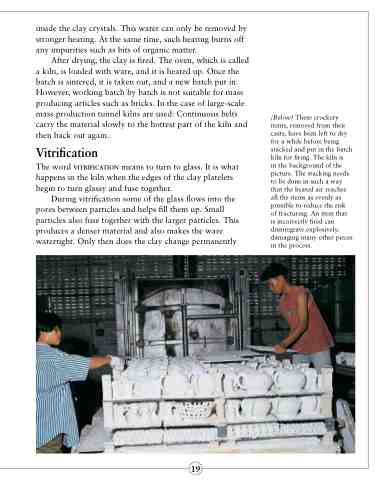

(Below) These crockery items, removed from their casts, have been left to dry for a while before being stacked and put in the batch kiln for firing. The kiln is

in the background of the picture. The stacking needs to be done in such a way that the heated air reaches all the items as evenly as possible to reduce the risk of fracturing. An item that is incorrectly fired can disintegrate explosively, damaging many other pieces in the process.

19