Page 23 - Curriculum Visions Dynamic Book

P. 23

a knife. Heating iron or steel in a fire and then beating it mixes some carbon atoms (from the fuel) into the surface. A final heating without beating allows some of the softness to return. This is the process called tempering.

Another way to harden a metal is to work it while it is cold, for example, by passing it under a hammer (a process called forging) or through rollers (called rolling). These actions break up the layers of atoms and so prevent them from easily moving past one another.

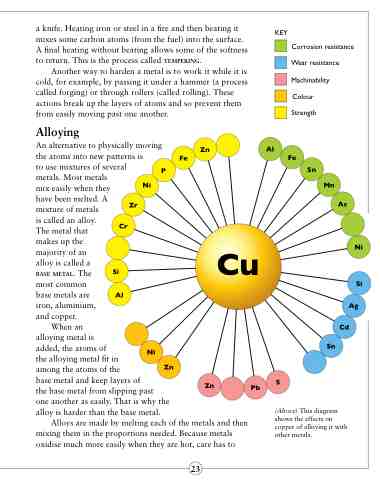

KEY

Corrosion resistance

Wear resistance Machinability

Colour Strength

Al

Fe

Alloying

An alternative to physically moving the atoms into new patterns is

Zn Fe

to use mixtures of several metals. Most metals

mix easily when they have been melted. A mixture of metals

is called an alloy.

The metal that

makes up the

majority of an

alloy is called a

base metal. The

most common

base metals are Al iron, aluminium,

and copper. When an

alloying metal is

added, the atoms of

the alloying metal fit in

among the atoms of the

base metal and keep layers of

the base metal from slipping past

one another as easily. That is why the alloy is harder than the base metal.

Sn

Cu

Zr Cr

As

Ni

Si Ag

Ni

Mn

P

Si

Ni

Zn

Sn

Cd

Alloys are made by melting each of the metals and then mixing them in the proportions needed. Because metals oxidise much more easily when they are hot, care has to

(Above) This diagram shows the effects on copper of alloying it with other metals.

Zn

S

Pb

23