Page 22 - Curriculum Visions Dynamic Book

P. 22

3: Changing the properties of a metal

All metals change when they are put under a pulling, pushing, or twisting force. If the force is small, the metal will bend a little. When the force is removed, the metal

will go back to its original position. This natural springiness is called an elastic change because the metal goes back to its original shape just as an elastic band would.

When more force is put on a metal, it

changes shape permanently. The metal can

no longer resist the force, and layers of atoms

begin to slide over one another. This is called a plastic change (not to be confused with plastic as

a material). When the material is changed in this way and the force removed, it will still have elastic properties as long as the force is small. For example, a paper clip has to be formed by applying enough force to bend the wire into shape. But when the wire has been shaped, it is springy (elastic) enough to be used as a clip.

Heating and beating

Some metals can be made stronger simply by repeatedly heating them in a fire and then beating them with a hammer. This

is commonly done to iron and titanium. It was traditionally the way that a blacksmith both shaped and hardened

his wares (see pages 12 and 13).

In some cases the metal needs to

have properties on the surface that are different from those inside. One example of this is when the surface of iron or steel has to be hardened, for instance, to make

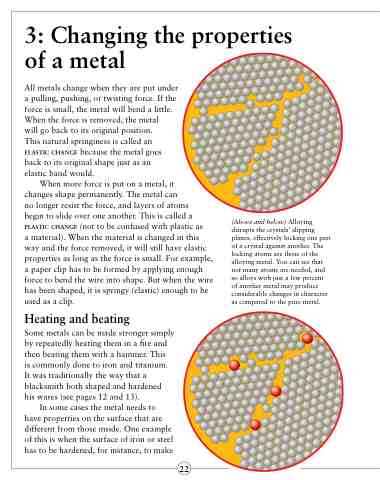

(Above and below) Alloying disrupts the crystals’ slipping planes, effectively locking one part of a crystal against another. The locking atoms are those of the alloying metal. You can see that not many atoms are needed, and so alloys with just a few percent of another metal may produce considerable changes in character as compared to the pure metal.

22