Page 20 - Curriculum Visions Dynamic Book

P. 20

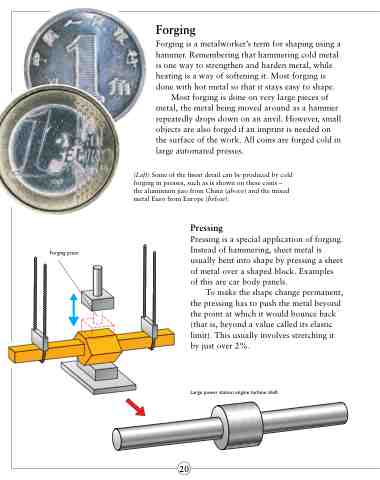

Forging press

Forging

Forging is a metalworker’s term for shaping using a hammer. Remembering that hammering cold metal is one way to strengthen and harden metal, while heating is a way of softening it. Most forging is done with hot metal so that it stays easy to shape.

Most forging is done on very large pieces of metal, the metal being moved around as a hammer repeatedly drops down on an anvil. However, small objects are also forged if an imprint is needed on the surface of the work. All coins are forged cold in large automated presses.

(Left) Some of the finest detail can be produced by cold forging in presses, such as is shown on these coins – the aluminium jiao from China (above) and the mixed metal Euro from Europe (below).

Pressing

Pressing is a special application of forging. Instead of hammering, sheet metal is usually bent into shape by pressing a sheet of metal over a shaped block. Examples

of this are car body panels.

To make the shape change permanent,

the pressing has to push the metal beyond the point at which it would bounce back (that is, beyond a value called its elastic limit). This usually involves stretching it by just over 2%.

Large power station engine turbine shaft

20