Page 25 - Curriculum Visions Dynamic Book

P. 25

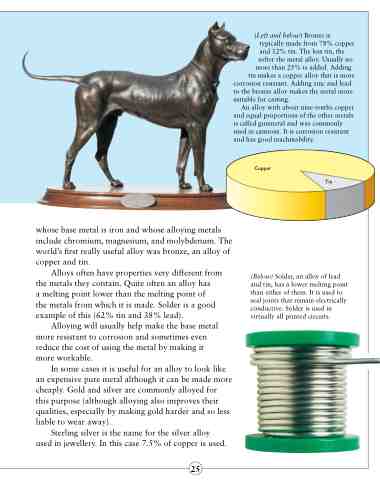

(Left and below) Bronze is typically made from 78% copper and 12% tin. The less tin, the

softer the metal alloy. Usually no more than 25% is added. Adding

tin makes a copper alloy that is more corrosion resistant. Adding zinc and lead to the bronze alloy makes the metal more suitable for casting.

An alloy with about nine-tenths copper and equal proportions of the other metals is called gunmetal and was commonly used in cannons. It is corrosion resistant and has good machinability.

Copper

Tin

whose base metal is iron and whose alloying metals include chromium, magnesium, and molybdenum. The world’s first really useful alloy was bronze, an alloy of copper and tin.

Alloys often have properties very different from the metals they contain. Quite often an alloy has

a melting point lower than the melting point of

the metals from which it is made. Solder is a good example of this (62% tin and 38% lead).

Alloying will usually help make the base metal more resistant to corrosion and sometimes even reduce the cost of using the metal by making it more workable.

In some cases it is useful for an alloy to look like an expensive pure metal although it can be made more cheaply. Gold and silver are commonly alloyed for

this purpose (although alloying also improves their qualities, especially by making gold harder and so less liable to wear away).

Sterling silver is the name for the silver alloy used in jewellery. In this case 7.5% of copper is used.

(Below) Solder, an alloy of lead and tin, has a lower melting point than either of them. It is used to seal joints that remain electrically conductive. Solder is used in virtually all printed circuits.

25