Page 23 - Curriculum Visions Dynamic Book

P. 23

flywheel to the bottom of the piston, it can be turned into a rotational movement, which can turn the wheels of a lathe, a loom, a tractor, a steam engine, or many other machines. It is both simple and reliable.

A more sophisticated form of steam engine (double- acting engine) lets in steam to each side of the piston in turn so that simple vacuum draw back is aided by more steam pressure. A series of valves controls the entry of steam at appropriate moments.

Steam turbines

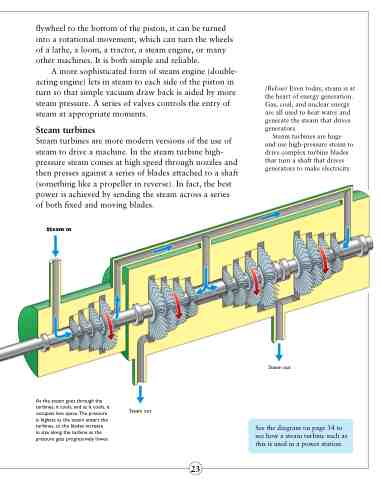

Steam turbines are more modern versions of the use of steam to drive a machine. In the steam turbine high- pressure steam comes at high speed through nozzles and then presses against a series of blades attached to a shaft (something like a propeller in reverse). In fact, the best power is achieved by sending the steam across a series of both fixed and moving blades.

(Below) Even today, steam is at the heart of energy generation. Gas, coal, and nuclear energy are all used to heat water and generate the steam that drives generators.

Steam turbines are huge and use high-pressure steam to drive complex turbine blades that turn a shaft that drives generators to make electricity.

Steam in

As the steam goes through the turbines, it cools, and as it cools, it occupies less space.The pressure is highest as the steam enters the turbines, so the blades increase

in size along the turbine as the pressure gets progressively lower.

Steam out

Steam out

See the diagram on page 34 to see how a steam turbine such as this is used in a power station.

23