Page 26 - Curriculum Visions Dynamic Book

P. 26

places where glass could cause injury, for example, in double glazing of

doors and shower glass. Tempered glass breaks into a large number of rounded pieces rather than into long, sharp shards.

To stress glass by

tempering, it has to be

heated until it is almost

soft, then cooled very

quickly in a controlled way. The inside cools after the outside so that the inside is still trying to cool and shrink when the outside of the glass has already set hard. That is what causes the pulling stress towards the centre, at the same time compressing the surface.

Glass can also be made safer by laminating it,

as for example, in car windshields. Bulletproof glass is often laminated, or layered. Laminated glass is a sandwich of glass and plastics. The inner part of the sandwich is made of a tough plastic. Not only does the plastic layer help absorb the energy of an impact, but the fact that the glass is stuck to the

plastic reduces the chances of sharp shards

flying away and injuring people.

Glass can also undergo chemical strengthening. In this method it is placed

in a hot bath (500°C) containing potassium

nitrate. Potassium atoms are larger than the

sodium atoms in the glass. When the glass

is hot, sodium atoms will swap places with potassium atoms close to the surface. Then,

when the glass cools, the larger potassium

atoms more than fill the spaces between the silicon atoms, leading to compression and strength. This process is used to strengthen eyeglass lenses and also aircraft windows.

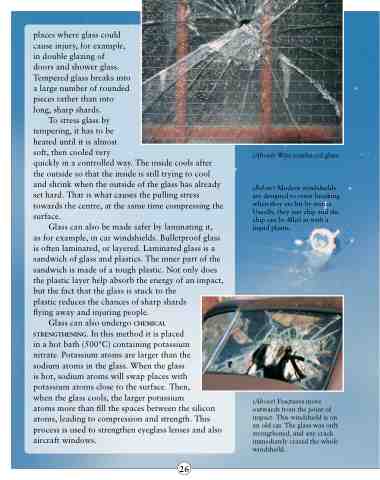

(Above) Wire-reinforced glass.

(Below) Modern windshields are designed to resist breaking when they are hit by stones. Usually, they just chip and the chip can be filled in with a liquid plastic.

26

(Above) Fractures move outwards from the point of impact. This windshield is on an old car. The glass was only strengthened, and any crack immediately crazed the whole windshield.