Page 17 - Curriculum Visions Dynamic Book

P. 17

Metal moulds produce a much smoother finish. In this case the mould is called a die. The die is machined out using lathes. The metal is often forced into the die under pressure to make sure it fills all of the intricate spaces of the die. This is known as die casting.

Die casts are not cooled in air but quenched in water. That allows the die to be reused quickly. Rapid water cooling also makes the casting stronger, but more brittle, than if it were cooled in air.

To mass produce very small parts, a pattern is made of wax, and then a coating of sand and mud is put on it. More coats are added until the sand and mud make

a rigid shell. The wax is then melted out. This method allows a very complex shape to be produced.

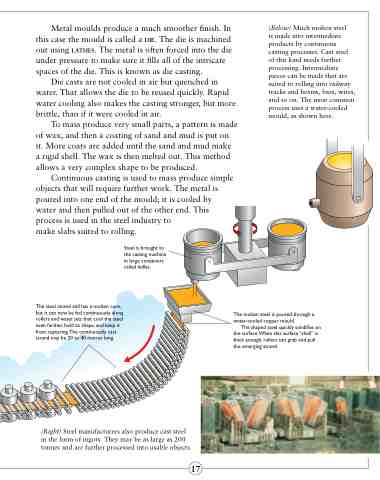

Continuous casting is used to mass produce simple objects that will require further work. The metal is poured into one end of the mould; it is cooled by water and then pulled out of the other end. This process is used in the steel industry to

make slabs suited to rolling.

Steel is brought to the casting machine in large containers called ladles.

The steel strand still has a molten core, but it can now be fed continuously along rollers and water jets that cool the steel even further, hold its shape, and keep it from rupturing.The continuously cast strand may be 20 to 40 metres long.

(Below) Much molten steel

is made into intermediate products by continuous casting processes. Cast steel of this kind needs further processing. Intermediate pieces can be made that are suited to rolling into railway tracks and beams, bars, wires, and so on. The most common process uses a water-cooled mould, as shown here.

The molten steel is poured through a water-cooled copper mould.

The shaped steel quickly solidifies on the surface.When this surface “shell” is thick enough, rollers can grab and pull the emerging strand.

(Right) Steel manufacturers also produce cast steel in the form of ingots. They may be as large as 200 tonnes and are further processed into usable objects.

17