Page 43 - Curriculum Visions Dynamic Book

P. 43

Lead solder and printed circuits

A printed circuit is an arrangement of electronic components, such as transistors and resistors, on a supporting board that is already printed with circuit wires.

The connections of the circuit are made with very thin layers of copper held in place by a glue. Too much heat and the glue will melt and the copper conductors will fall off the printed circuit board. The electronic components are equally delicate, and heat may easily crack them.

The key to making mass-produced printed circuits, found in everything from computers to washing machines, is to join the components to the copper on the board speedily and with as little heat as possible.

To do this the components are all pushed through

holes in the board, and then the copper side is exposed. The protruding component wires are then soldered to the copper by passing them through an automatic soldering machine that applies just the right amount of solder for just the right length of time to make the correct joint before the board or components have the time to heat up too much.

capillary action: the tendency of a liquid to be sucked into small spaces, such as between objects and through narrow-pore tubes. The force to do this comes from surface tension.

flux: a material used to make it easier for a liquid to flow.

A flux dissolves metal oxides and so prevents a metal from oxidising while being heated.

tarnish: a coating that develops as a result of the reaction between a metal and substances in the air. The most common form of tarnishing is a very

thin transparent oxide coating.

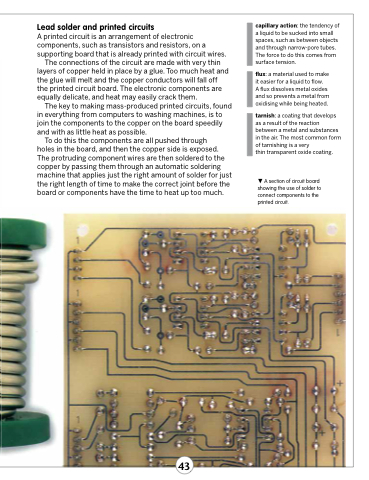

A section of circuit board showing the use of solder to connect components to the printed circuit.

43 43