Page 38 - Curriculum Visions Dynamic Book

P. 38

Tin plating

As soon as tin metal is exposed to the air,

it develops a strong, gastight coating that prevents it from being corroded further. Although iron

is next to tin in the reactivity series, the oxide coating that develops on iron is porous, which

is why iron rusts. Thus tin (oxide) behaves very differently from iron. The low melting point of tin also means that it is easy to run sheet steel through a bath of tin without any fear that the steel might melt. These twin advantages have given tin its major use: as a way of protecting steel.

Food containers

The advantage of tin is best seen in its use for food containers. Many foods contain organic acids. However, tin remains unreactive and so can be used for the inside of food cans because the food will

not corrode the can. Tin plating was developed as a means of preserving moist food so that it could be taken to military forces when on active service. The French were among the first to try to invent a preserving process. In 1795 a Parisian chef, Nicolas Appert, invented the canning process. However, as tin-coated steel had not at

that time been invented, his process actually involved preserving cooked food in bottles. Bottles are not a good means of carrying

food because of the risk of breakage. A new material had to be found. The tin-coated metal can was invented in Britain in 1810, and it was at this time that the word canning came into general use.

The value of the tin can was that the strength and cheapness of thin steel

could be complemented by the corrosion resistance of soft tin. Plating the steel

(which had to be done both inside and out) prevented the steel from rusting. The steel plate was curled into a cylinder and the seam made tight using a solder join. The top and bottom of the can could be fixed on with

a press.

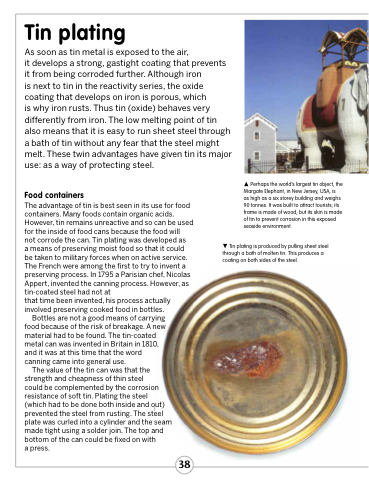

Perhaps the world’s largest tin object, the Margate Elephant, in New Jersey, USA, is

as high as a six storey building and weighs 90 tonnes. It was built to attract tourists; its frame is made of wood, but its skin is made of tin to prevent corrosion in this exposed seaside environment.

Tin plating is produced by pulling sheet steel through a bath of molten tin. This produces a coating on both sides of the steel.

38