Page 36 - Curriculum Visions Dynamic Book

P. 36

Placer tin mining

Four-fifths of the world’s tin is obtained from placer deposits. Most placer deposits use high-pressure hoses to wash out the tin from deposits, or they use some form of excavator to dredge it from under the sea.

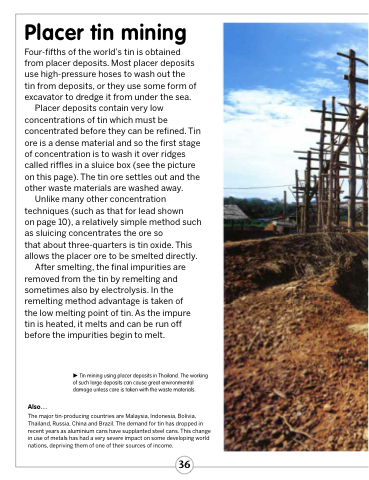

Placer deposits contain very low concentrations of tin which must be concentrated before they can be refined. Tin ore is a dense material and so the first stage of concentration is to wash it over ridges called riffles in a sluice box (see the picture on this page). The tin ore settles out and the other waste materials are washed away.

Unlike many other concentration techniques (such as that for lead shown

on page 10), a relatively simple method such as sluicing concentrates the ore so

that about three-quarters is tin oxide. This allows the placer ore to be smelted directly.

After smelting, the final impurities are removed from the tin by remelting and sometimes also by electrolysis. In the remelting method advantage is taken of the low melting point of tin. As the impure tin is heated, it melts and can be run off before the impurities begin to melt.

Tin mining using placer deposits in Thailand. The working of such large deposits can cause great environmental damage unless care is taken with the waste materials.

Also...

The major tin-producing countries are Malaysia, Indonesia, Bolivia, Thailand, Russia, China and Brazil. The demand for tin has dropped in recent years as aluminium cans have supplanted steel cans. This change in use of metals has had a very severe impact on some developing world nations, depriving them of one of their sources of income.

36