Page 10 - Curriculum Visions Dynamic Book

P. 10

Mining and smelting copper ores

About nine-tenths of the world’s reserves of copper are found in

just four areas: the great Basin of the western United States, central Canada, the Andes regions of Peru and Chile, and Zambia. In each case the extraction of copper is of crucial importance to the country. In the case of Zambia the reserves are the mainstay of the country’s economy, with a chain of major cities making up the “Copper Belt”. The largest deposit of copper in the world is at Chuquicamata, Chile, but the largest refiner of copper is the United States, which also boasts the world’s largest copper mine, in Utah.

The amount of copper in the ground is relatively small and

most of it occurs in low-grade ores that have to be processed twice to extract the copper. This is why it is important to reuse as much copper as possible, and why about one-third of copper consumed in most industrial countries is recycled from scrap.

Mining

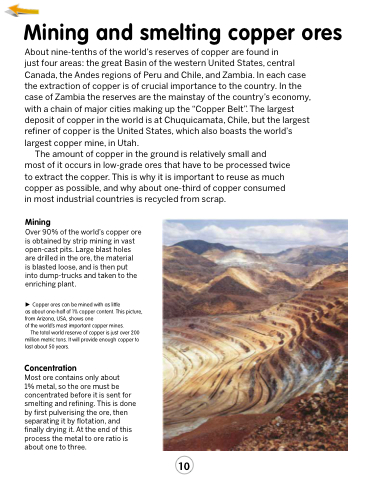

Over 90% of the world’s copper ore is obtained by strip mining in vast open-cast pits. Large blast holes are drilled in the ore, the material

is blasted loose, and is then put into dump-trucks and taken to the enriching plant.

Copper ores can be mined with as little

as about one-half of 1% copper content. This picture, from Arizona, USA, shows one

of the world’s most important copper mines.

The total world reserve of copper is just over 200 million metric tons. It will provide enough copper to last about 50 years.

Concentration

Most ore contains only about

1% metal, so the ore must be concentrated before it is sent for smelting and refining. This is done by first pulverising the ore, then separating it by flotation, and finally drying it. At the end of this process the metal to ore ratio is about one to three.

10

10