Page 24 - Curriculum Visions Dynamic Book

P. 24

Smelting iron ore

Processing, or smelting, iron ore is done in a blast furnace, a tall oven designed to produce the high temperatures needed to melt and refine iron oxide.

In essence the furnace has to remove the oxygen from the metal ore (the ore must be reduced) and the waste rock

must be separated from the valuable metal. This is done with a very hot blast

of carbon monoxide gas. The whole furnace is built so that hot carbon monoxide gas is continuously produced and blown through melting rock. The heavy slag and molten iron escape from the bottom of the furnace, and a charge

of new ore and fuel is applied at the top. In this way the blast furnace can be operated continuously.

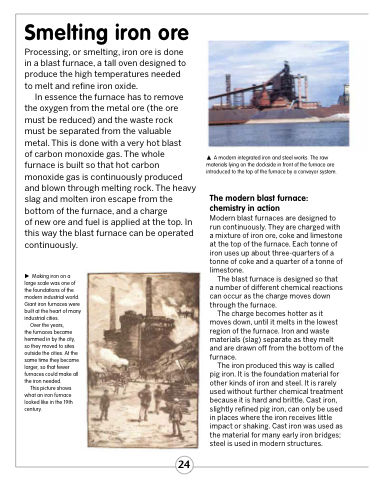

Making iron on a large scale was one of the foundations of the modern industrial world. Giant iron furnaces were built at the heart of many industrial cities.

Over the years,

the furnaces became hemmed in by the city, so they moved to sites outside the cities. At the same time they became larger, so that fewer furnaces could make all the iron needed.

This picture shows what an iron furnace looked like in the 19th century.

A modern integrated iron and steel works. The raw materials lying on the dockside in front of the furnace are introduced to the top of the furnace by a conveyor system.

The modern blast furnace: chemistry in action

Modern blast furnaces are designed to run continuously. They are charged with a mixture of iron ore, coke and limestone at the top of the furnace. Each tonne of iron uses up about three-quarters of a tonne of coke and a quarter of a tonne of limestone.

The blast furnace is designed so that a number of different chemical reactions can occur as the charge moves down through the furnace.

The charge becomes hotter as it moves down, until it melts in the lowest region of the furnace. Iron and waste materials (slag) separate as they melt and are drawn off from the bottom of the furnace.

The iron produced this way is called pig iron. It is the foundation material for other kinds of iron and steel. It is rarely used without further chemical treatment because it is hard and brittle. Cast iron, slightly refined pig iron, can only be used in places where the iron receives little impact or shaking. Cast iron was used as the material for many early iron bridges; steel is used in modern structures.

24