Page 42 - Curriculum Visions Dynamic Book

P. 42

Polyester fibre

Polyester makes up over half of all man-

made fibre production. Its most common

form is called PET or PETE (polyethene terephthalate). A considerable amount of polyester fibre is produced by recycling PET soft drink bottles and thus saving on petroleum supplies and avoiding landfill problems.

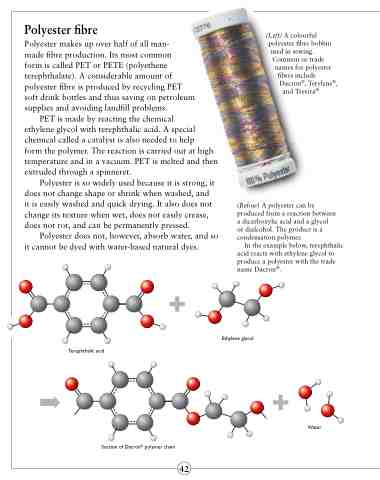

PET is made by reacting the chemical

ethylene glycol with terephthalic acid. A special chemical called a catalyst is also needed to help

form the polymer. The reaction is carried out at high temperature and in a vacuum. PET is melted and then extruded through a spinneret.

Polyester is so widely used because it is strong, it

does not change shape or shrink when washed, and

(Left) A colourful polyester fibre bobbin

used in sewing. Common or trade

names for polyester fibres include

Dacron®, Terylene®, and Trevira®.

it is easily washed and quick drying. It also does not (Below) A polyester can be

change its texture when wet, does not easily crease, does not rot, and can be permanently pressed.

produced from a reaction between a dicarboxylic acid and a glycol or dialcohol. The product is a

Polyester does not, however, absorb water, and so condensation polymer.

it cannot be dyed with water-based natural dyes.

In the example below, terephthalic acid reacts with ethylene glycol to produce a polyester with the trade name Dacron®.

Terephthalic acid

Ethylene glycol

Section of Dacron® polymer chain

Water

42