Page 29 - Curriculum Visions Dynamic Book

P. 29

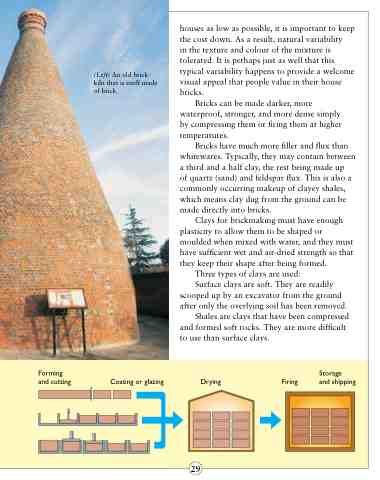

(Left) An old brick kiln that is itself made of brick.

houses as low as possible, it is important to keep the cost down. As a result, natural variability

in the texture and colour of the mixture is tolerated. It is perhaps just as well that this typical variability happens to provide a welcome visual appeal that people value in their house bricks.

Bricks can be made darker, more waterproof, stronger, and more dense simply by compressing them or firing them at higher temperatures.

Bricks have much more filler and flux than whitewares. Typically, they may contain between a third and a half clay, the rest being made up

of quartz (sand) and feldspar flux. This is also a commonly occurring makeup of clayey shales, which means clay dug from the ground can be made directly into bricks.

Clays for brickmaking must have enough plasticity to allow them to be shaped or moulded when mixed with water, and they must have sufficient wet and air-dried strength so that they keep their shape after being formed.

Three types of clays are used:

Surface clays are soft. They are readily scooped up by an excavator from the ground after only the overlying soil has been removed.

Shales are clays that have been compressed and formed soft rocks. They are more difficult to use than surface clays.

Forming

and cutting Coating or glazing

Storage Drying Firing and shipping

29