Page 34 - Curriculum Visions Dynamic Book

P. 34

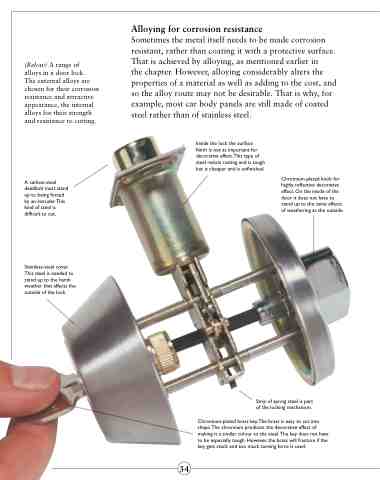

(Below) A range of

alloys in a door lock.

The external alloys are chosen for their corrosion resistance and attractive appearance, the internal alloys for their strength and resistance to cutting.

A carbon-steel deadbolt must stand up to being forced by an intruder.This kind of steel is difficult to cut.

Stainless-steel cover. This steel is needed to stand up to the harsh weather that affects the outside of the lock.

Alloying for corrosion resistance

Sometimes the metal itself needs to be made corrosion resistant, rather than coating it with a protective surface. That is achieved by alloying, as mentioned earlier in

the chapter. However, alloying considerably alters the properties of a material as well as adding to the cost, and so the alloy route may not be desirable. That is why, for example, most car body panels are still made of coated steel rather than of stainless steel.

Inside the lock the surface finish is not as important for decorative effect.This type of steel resists rusting and is tough but is cheaper and is unfinished.

Chromium-plated knob for highly reflective decorative effect. On the inside of the door it does not have to stand up to the same effects of weathering as the outside.

Strip of spring steel is part of the locking mechanism.

Chromium-plated brass key.The brass is easy to cut into shape.The chromium produces the decorative effect of making it a similar colour to the steel.The key does not have to be especially tough. However, the brass will fracture if the key gets stuck and too much turning force is used.

34