Page 33 - Curriculum Visions Dynamic Book

P. 33

A great range of polymers

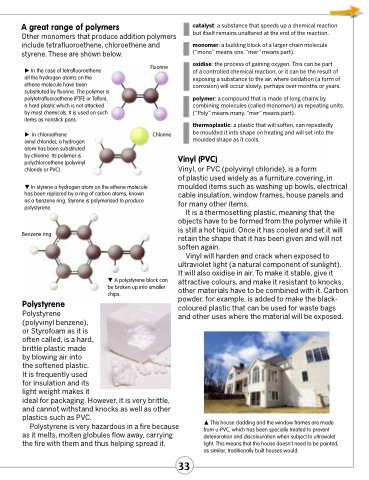

Other monomers that produce addition polymers include tetrafluoroethene, chloroethene and styrene. These are shown below.

catalyst: a substance that speeds up a chemical reaction but itself remains unaltered at the end of the reaction.

monomer: a building block of a larger chain molecule (“mono” means one, “mer” means part).

oxidise: the process of gaining oxygen. This can be part

of a controlled chemical reaction, or it can be the result of exposing a substance to the air, where oxidation (a form of corrosion) will occur slowly, perhaps over months or years.

polymer: a compound that is made of long chains by combining molecules (called monomers) as repeating units. (“Poly” means many, “mer” means part).

thermoplastic: a plastic that will soften, can repeatedly be moulded it into shape on heating and will set into the moulded shape as it cools.

In the case of tetrafluoroethene

all the hydrogen atoms on the ethene molecule have been substituted by fluorine. The polymer is polytetrafluoroethene (PTFE or Teflon), a hard plastic which is not attacked by most chemicals. It is used on such items as nonstick pans.

In chloroethene

(vinyl chloride), a hydrogen atom has been substituted by chlorine. Its polymer is polychloroethene (polyvinyl chloride or PVC).

In styrene a hydrogen atom on the ethene molecule has been replaced by a ring of carbon atoms, known as a benzene ring. Styrene is polymerised to produce polystyrene.

Fluorine

Chlorine

Benzene ring

Polystyrene

A polystyrene block can be broken up into smaller chips.

Vinyl (PVC)

Vinyl, or PVC (polyvinyl chloride), is a form

of plastic used widely as a furniture covering, in moulded items such as washing up bowls, electrical cable insulation, window frames, house panels and for many other items.

It is a thermosetting plastic, meaning that the objects have to be formed from the polymer while it is still a hot liquid. Once it has cooled and set it will retain the shape that it has been given and will not soften again.

Vinyl will harden and crack when exposed to ultraviolet light (a natural component of sunlight). It will also oxidise in air. To make it stable, give it attractive colours, and make it resistant to knocks, other materials have to be combined with it. Carbon powder, for example, is added to make the black- coloured plastic that can be used for waste bags and other uses where the material will be exposed.

Polystyrene

(polyvinyl benzene),

or Styrofoam as it is

often called, is a hard,

brittle plastic made

by blowing air into

the softened plastic.

It is frequently used

for insulation and its

light weight makes it

ideal for packaging. However, it is very brittle, and cannot withstand knocks as well as other plastics such as PVC.

This house cladding and the window frames are made from u-PVC, which has been specially treated to prevent deterioration and discolouration when subject to ultraviolet light. This means that the house doesn’t need to be painted, as similar, traditionally built houses would.

Polystyrene is very hazardous in a fire because as it melts, molten globules flow away, carrying the fire with them and thus helping spread it.

33

33