Page 22 - Curriculum Visions Dynamic Book

P. 22

Aluminium alloys

Pure aluminium is easy to bend and form into shape, but it is not very strong. An alloy is a mixture of various elements, designed to give the alloy special characteristics that pure metals do

not have.

Common alloys

Normal refining processes do not remove all impurities from aluminium, so most commonly used industrial aluminium already has small amounts of iron, silicon and copper alloyed

with it. Fortunately, alloying elements make aluminium stronger, but it remains easy to bend into shape.

The most common alloy of aluminium contains copper, magnesium, manganese, chromium, silicon, iron, nickel and zinc. Here silicon

makes the aluminium flow better into casts of complicated shapes. Copper, on the other hand, makes the aluminium stronger. Adding 1.25% manganese makes the alloy exceptionally resistant to corrosion.

In all cases, the proportion of added elements is less than 10% of the final alloy; and because silicon mixes quite poorly in an alloy, no more than about 1.5% can be used.

Modern aircraft engine makers and power station turbine makers are working with new alloys that contain titanium or nickel to make lightweight aluminium even tougher.

Alloys that are forced into new shapes

For many purposes the aluminium alloy needs to be forced into a new shape, for example made into a tube or pressed into a car body panel.

The best alloys for this have a slightly different composition to those used for casting. These alloys get stronger and harder as they are worked, often at high temperatures.

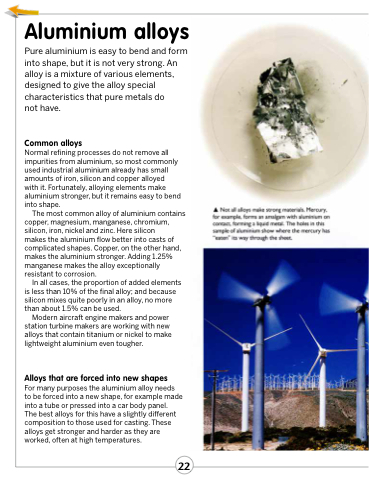

Not all alloys make strong materials. Mercury, for example, forms an amalgam with aluminium on contact, forming a liquid metal. The holes in this sample of aluminium show where the mercury has “eaten” its way through the sheet.

22

22